1. Optimum utilization of materials: Coated two-ply board is known for its high stiffness and thickness, allowing it to provide structural integrity while using less material. This reduces the overall weight and volume of the packaging, thereby reducing waste generation.

First, the high stiffness and good paper quality of coated two-ply board make it capable of supporting various types of packaging. This means less paper can be used per packaging unit, reducing material usage. Compared with other thinner or less rigid materials, coated two-ply board paper can reduce the use of material while ensuring the structural integrity of the package, thereby reducing the need for packaging materials.

In addition, the high thickness of coated two-ply board paper makes it an ideal choice for packaging materials, as it can withstand heavy pressure and stacking without being easily deformed or damaged. This means that the coated double-ply board paper is not easily damaged during use and does not require additional packaging material to protect the contents inside, further reducing waste generation.

2. Improvement of printing quality: The smooth coating surface of coated double-layer board paper can realize high-quality printing. This means that packaging can be designed more efficiently, reducing the need for additional labeling or printed material, reducing the source of waste generation.

The quality of fine print can enhance the attractiveness of packaging and make the brand more recognizable and memorable. This helps reduce unnecessary secondary packaging, such as overlay labels or boxes, reducing packaging material usage and waste generation.

3. Improve packaging durability: Coated double-layer board paper has strong abrasion resistance and tear resistance. This durability reduces the likelihood of cargo being damaged during transit, reducing the need to change packaging and thus reducing waste generation.

Packaging may be subjected to crushing, vibration and other stresses during shipping and handling. Coated two-ply board can effectively meet these challenges, protecting the packaged goods from damage, reducing the need for repackaging due to damage, and reducing waste generation.

4. Recyclability: Coated double-ply board paper is usually manufactured with an emphasis on recyclability. Many packaging manufacturers use recycled materials to make coated plyboard, and it can be easily recycled after its initial use. This closed-loop recycling process reduces waste generation in the supply chain.

Some coated two-ply boards are even made from 100% recycled pulp, further reducing the need for virgin pulp. This helps reduce resource consumption and environmental impact, and promotes sustainable development.

5. Sustainable Sourcing: Some coated two-ply boards are produced using sustainable forestry practices and environmentally friendly manufacturing processes. This reduces the environmental impact associated with paper production and promotes responsible resource management.

Sustainably sourcing coated two-plyboard means adopting sustainable forest management practices that ensure forest resources are conserved and regenerated. At the same time, adopting an environmentally friendly manufacturing process can reduce energy consumption, waste generation, and discharge of chemical substances, helping to reduce environmental burdens.

6. Lightweight design: Coated double-layer board paper allows to make light and strong packaging solutions. Lightweight packaging reduces transport costs and associated emissions, helping to reduce waste during the logistics phase.

Lightweight design does double duty in reducing waste. First, it reduces packaging material requirements, as less material is used to create lightweight packaging. Second, it reduces energy consumption and emissions during the transport phase, as lighter packaging requires less fuel to transport.

7. Customization and Design Efficiency: The versatility of coated double-ply board paper allows for the creation of packaging solutions customized for specific products. This means packaging can be designed according to the shape and size of the product to reduce empty space and unnecessary material usage, resulting in lower waste generation.

Customized packaging design can also improve the efficiency of packaging. For example, creating custom packaging for different types of products can ensure that the product will fit in the package, reducing movement and friction, reducing the risk of damage and thus reducing the need for repackaging.

8. Service life: Coated double-layer board paper can resist various environmental conditions, such as humidity and temperature fluctuations, ensuring that the product is well protected during its life cycle. This reduces the need for repackaging or disposal due to damage, reducing waste generation.

Some products may require prolonged storage, and the durability of coated plyboard means it can withstand prolonged storage and transport without damage. This helps reduce waste due to packaging issues, as durable packaging maintains its integrity over a long period of time.

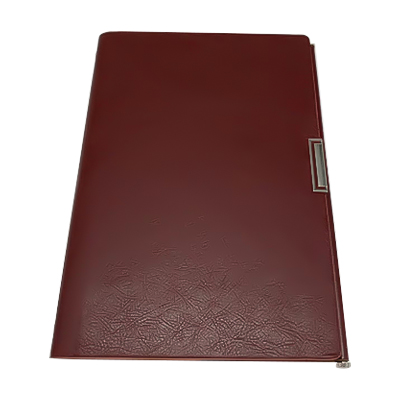

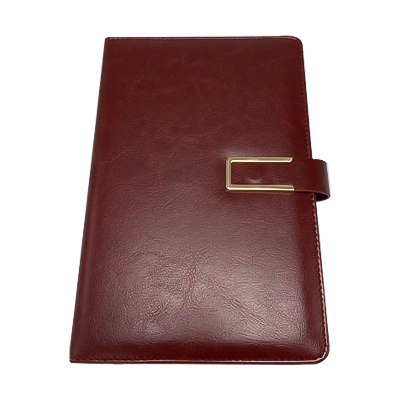

Coated White Card Paper IBS-Reel Paper

Coated White Card Paper IBS-Reel Paper

BASIS WEIGHT g/㎡:190/210/230

PACKAGING:Reel with Kraft Paper Wrapped

Cost-effective. Good for ordinary printing. Stable quality and good performance. Can be made of Postcard, card, etc.

English

English Deutsch

Deutsch Français

Français Español

Español русский

русский عربى

عربى